×

- Home

- Corporate

- About Us

- Vision-Mission

- Our Quality Policy

- Our Facilities

- News From ELC

- Personal Data Protection Law

- KVKK Application Form

- Promotional Film

- Productions

- Standart Profiles

- Furniture Profiles

- Railing Profiles

- Fenster & Türen Profile

- Facade System Profiles

- Sliding System Profiles

- Glass Balcony Profiles

- Bath Cabınet

- Insert Screen & Shutter Profiles

- Automotive Profiles

- White Goods Profiles

- Machine Profiles

- Advertisement Profiles

- Solar Construction System Profiles

- Steel Door Profiles

- Vent Profıles

- Other Profiles

- ONLINE KATALOG

- Archminium AR55

- Archminium AR70

- ELC Solar

- Carrier

- Contact

☰

TR

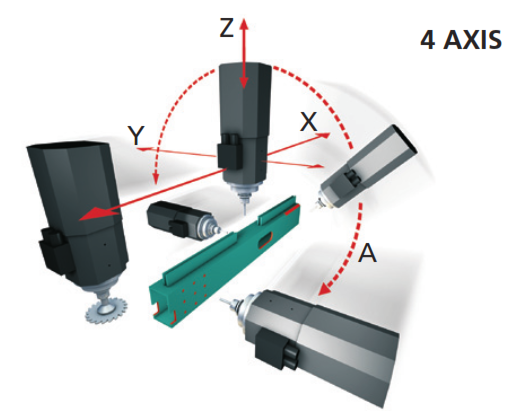

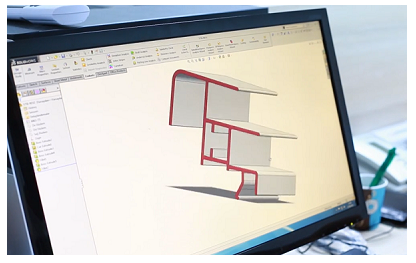

TR  RESEARCH & DEVELOPMENT:

RESEARCH & DEVELOPMENT:

ANODIZING:

ANODIZING: POLISHING & SATINATING:

POLISHING & SATINATING: POWDER COATING:

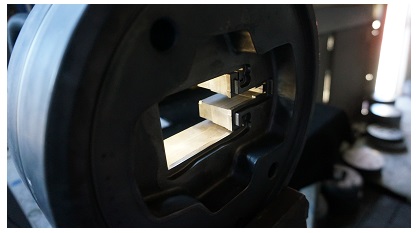

POWDER COATING: MECHANICAL TREATMENT:

MECHANICAL TREATMENT: